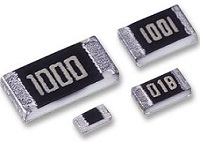

Surface Mount Resistors

RG ALLEN Surface Mount Resistors:

Surface mount resistors (SMD resistors) are a type of electronic component designed for use in surface mount technology (SMT) applications. They are widely used in the electronics industry due to their compact size, high reliability, and ease of automated assembly.- Surface Mount Resistor Index

- Thin Film Chip Resistors

- Thick Film Chip Resistors

- Thick Film Chip Resistor Arrays

- Thick Film Chip Network Arrays

Surface mount resistors offer several advantages, including space-saving design, improved signal integrity, and high reliability due to their low-profile construction and compatibility with automated assembly processes. They have become the preferred choice for most surface mount applications, allowing for smaller and more efficient electronic devices.

We produce a variety of high quality resistors from general-purpose resistors to power resistors. Please check our product lineup including precision resistors, low ohm type, shunt resistors, etc. Using Surface-mount technology (SMT) improves manufacturing, enabling very high levels of automation and in addition to this the use of SMT improves reliability, enables greater levels of functionality to be achieved within a reasonable size and reduces costs significantly.

We produce a variety of high quality resistors from general-purpose resistors to power resistors. Please check our product lineup including precision resistors, low ohm type, shunt resistors, etc. Using Surface-mount technology (SMT) improves manufacturing, enabling very high levels of automation and in addition to this the use of SMT improves reliability, enables greater levels of functionality to be achieved within a reasonable size and reduces costs significantly.

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). An electronic device so made is called a surface-mount device (SMD). An SMT component is usually smaller than its through-hole counterpart because it has either smaller leads or no leads at all. Surface mount device , SMD, resistors are the most widely used electronic component. Chip surface mount (SMD) resistors suiting a wide variety of applications, including various types of ferrite and suppression filters. Chip SMD resistors have advantages over more traditional through-hole resistors, such as lower cost and easier automation of assembly.

| Typical Surface Mount Resistor Power Usage | ||

|---|---|---|

| PACKAGE STYLE | Typical Power Rating (W) | |

| 2512 | 0.50 (1/2) | |

| 2010 | 0.25 (1/4) | |

| 1210 | 0.25 (1/4) | |

| 1206 | 0.125 (1/8) | |

| 0805 | 0.1 (1/10) | |

| 0603 | 0.0625 (1/16) | |

| 0402 | 0.0625 - 0.031 (1/16 - 1/32) | |

| 0201 | 0.05 | |

Surface mount device , SMD, resistors are the most widely used electronic component. Every day millions of these surface mount resistors are used to make electronics from cell phones to televisions and MP3 players, and commercial communications equipment to high technology research equipment.

Surface Mount Device (SMD) resistors are compact electronic components used to limit current flow in a circuit, control voltage levels, and divide voltages. They are designed for surface-mount applications, meaning they are soldered directly onto the surface of a printed circuit board (PCB) without the need for leads or wires. Here's an overview of SMD resistors:

Surface mount resistors are vital components in modern electronics, providing precise resistance values in a compact and surface-mountable form factor. Their versatility and wide range of types make them suitable for various applications across industries, contributing to the miniaturization and efficiency of electronic devices.

Construction:

-

Size: SMD resistors are significantly smaller than through-hole resistors, making them ideal for miniaturized electronics and densely populated PCBs.

-

Construction Materials: They are typically made from a ceramic substrate coated with a resistive material such as ruthenium oxide, nichrome, or tantalum nitride.

-

Encapsulation: SMD resistors are encapsulated in a protective layer, usually a polymer, to shield them from environmental factors such as moisture and contaminants.

Types:

- Standard Resistors:These are the most common types of SMD resistors and come in various configurations including:

- Chip Resistors (RC): Rectangular in shape, they are the most basic form of SMD resistors.

- Array Resistors: Multiple resistors are integrated into a single package, saving space and simplifying PCB layout.

- Network Resistors: Several resistors are interconnected within a single package, offering precise resistor ratios for voltage dividers and other applications.

- Specialized Resistors:There are also specialized types designed for specific applications, such as:

- High-Power SMD Resistors: Designed to handle higher power dissipation compared to standard SMD resistors.

- Thin-Film Resistors: Constructed using thin film deposition techniques, offering high precision and stability.

- Thick-Film Resistors: Made using thick film printing techniques, they are more cost-effective but may sacrifice precision compared to thin-film resistors.

Advantages:

-

Space Efficiency: SMD resistors are compact, allowing for smaller and more compact circuit designs.

-

Automated Assembly: Their surface-mount design allows for efficient and cost-effective automated assembly processes.

-

Improved Thermal Performance: SMD resistors have better heat dissipation characteristics due to their direct contact with the PCB.

Applications:

-

Consumer Electronics: Used in smartphones, tablets, laptops, and other consumer electronic devices.

-

Automotive Electronics: Found in vehicle control systems, infotainment systems, and various electronic modules.

-

Industrial Equipment: Used in control systems, power supplies, and instrumentation.

-

Telecommunications: Commonly employed in routers, switches, and communication equipment.

-

Medical Devices: Found in medical instruments and diagnostic equipment.

Identification:

-

Markings: SMD resistors are marked with alphanumeric codes indicating their resistance value, tolerance, and sometimes power rating.

-

Color Coding: Some SMD resistors use color codes similar to traditional resistors, but they are typically not as common due to limited space.

Considerations:

-

Precision: Thin-film resistors offer higher precision and stability compared to thick-film resistors.

-

Power Rating: Ensure the selected SMD resistor can handle the maximum power dissipation required for the application.

-

Tolerance: The tolerance indicates how close the actual resistance of the resistor is to its stated value. Common tolerances include 1%, 5%, and 10%.